Are you curious about the process of city gas excavation? How is it done safely, and why is it essential for urban infrastructure? Learn all the important aspects of city gas excavation work and the role it plays in maintaining gas systems in cities.

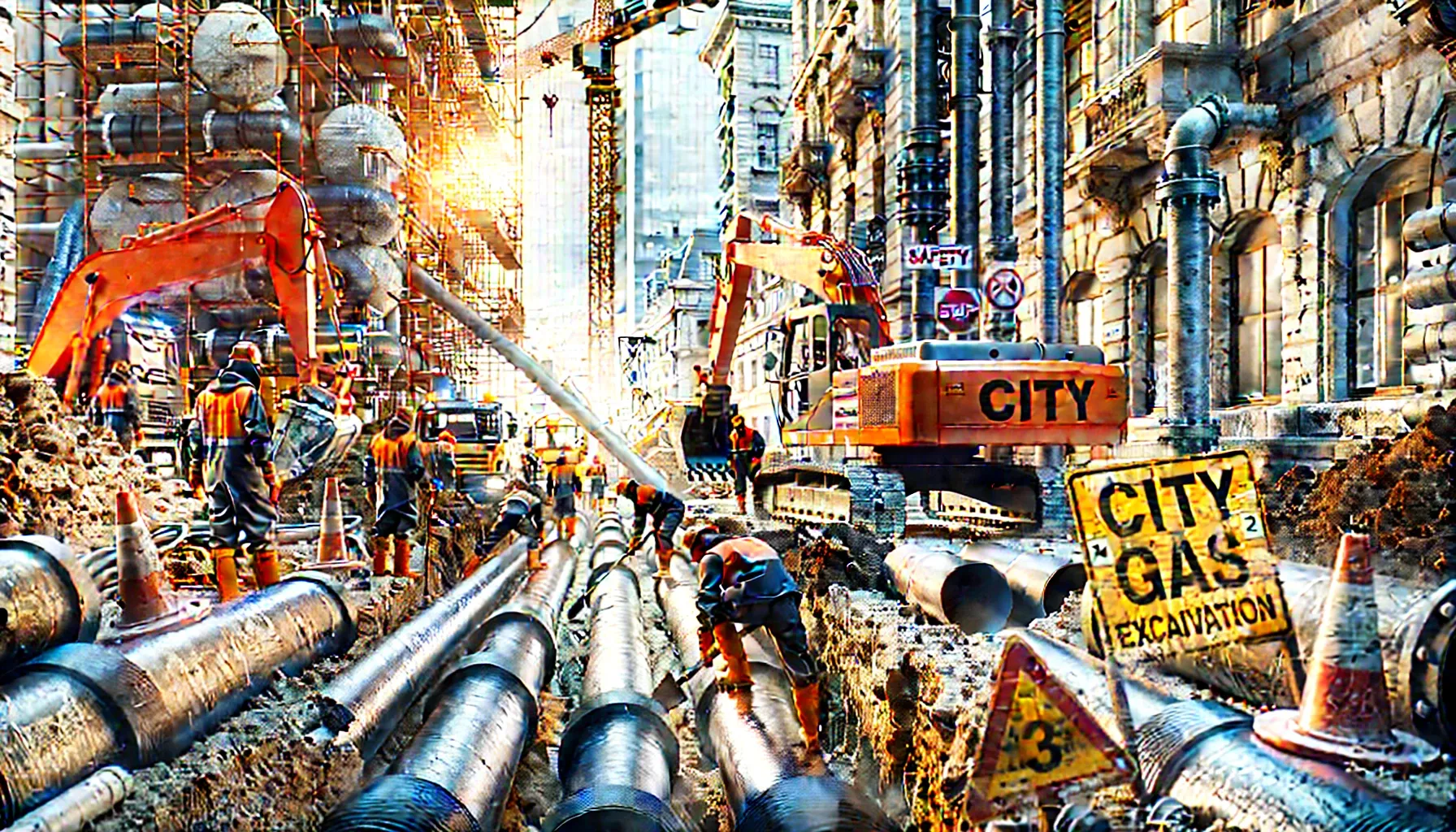

City Gas Excavation

City gas excavation is a critical process that plays a vital role in maintaining the infrastructure of urban environments. It involves the careful digging around gas lines to perform repairs, upgrades, or maintenance. In cities, the need for such excavation arises from various factors including wear and tear of old gas pipes, the installation of new pipelines, and routine checks for safety and functionality. Understanding the scope and methodology behind gas excavation can help ensure that safety standards are met, and the gas system remains in optimal condition.

Importance of City Gas Excavation

City gas excavation serves several essential purposes, such as:

-

Repairing or Replacing Old Pipes: Over time, gas pipelines can deteriorate due to environmental factors, wear, or corrosion. Excavation allows workers to assess the condition of the pipes and perform necessary repairs or replacements.

-

Upgrading Infrastructure: As cities grow, there is an increasing demand for gas supply. Excavation work allows for the installation of new gas pipelines to meet the needs of expanding populations.

-

Safety Inspections: Regular excavation work ensures the safety of gas systems by checking for leaks, damages, and ensuring proper gas flow.

-

Maintenance for Future Use: Excavating gas lines as part of preventive maintenance helps in prolonging the life of the infrastructure and minimizes the risk of major failures.

How the Excavation Process Works

The process of city gas excavation involves the following key steps:

-

Planning and Surveying: Before excavation begins, a detailed survey of the area is conducted to ensure there are no unintended damages to surrounding utilities.

-

Marking and Safety Measures: Excavation zones are clearly marked, and necessary safety measures, such as signage and barriers, are put in place to protect workers and pedestrians.

-

Excavation: Heavy machinery, such as backhoes or excavators, is used to dig safely around the gas lines. This stage is critical because the digging must avoid damaging the gas pipes.

-

Pipe Inspection and Repair: Once the gas pipes are exposed, they are inspected for signs of wear, corrosion, or damage. Necessary repairs or replacements are then carried out.

-

Backfilling and Restoration: After the work is completed, the excavation site is backfilled and restored to its original condition.

👉 Learn more about city gas excavation work 👈

City Gas Excavation Work

City gas excavation work is highly specialized, requiring skilled professionals to ensure both safety and accuracy. This type of excavation isn’t as straightforward as other construction tasks due to the inherent risks of working with gas lines. Workers must adhere to strict safety protocols to avoid accidents, including explosions or leaks, which can have devastating consequences.

Key Components of City Gas Excavation Work

-

Gas Detection Systems: Workers utilize gas detectors to monitor gas levels before, during, and after excavation. This helps to identify potential leaks in real-time.

-

Proper Equipment Use: Specialized excavation equipment such as vacuum excavators, air spades, and hand tools is used to safely dig around gas pipes without causing any damage.

-

Trenching and Shoring: Excavating deep trenches requires proper shoring to prevent cave-ins, especially in areas with unstable soil conditions.

-

Worker Training and Certification: Excavation teams are required to undergo specific training and certification to handle gas systems, ensuring they are qualified to deal with high-risk environments.

-

Emergency Response Plans: Before excavation begins, emergency plans are set in place to deal with any potential gas leaks or accidents.

Real-World Application: Case Study of a Major City Gas Excavation Project

For instance, in a recent project in a major city, excavation teams were tasked with replacing outdated gas lines beneath a busy urban street. The work required careful planning, including notifying the public of traffic disruptions and implementing advanced gas leak detection equipment to ensure that any leaks were immediately detected. The excavation was completed without incident, and the new pipes have been in use for several years, demonstrating the effectiveness of well-executed city gas excavation work.

👉 Find out about safety regulations for gas excavation work 👈

Gas Excavation

Gas excavation, a term often used interchangeably with city gas excavation, refers to the process of digging around existing gas pipelines to access, repair, or install new sections of pipe. It is an integral part of maintaining and expanding gas supply networks in both rural and urban areas.

The Risks of Gas Excavation

The nature of gas excavation presents certain risks, including:

-

Gas Leaks: The most significant danger in gas excavation is the risk of causing a gas leak, which can lead to explosions or poisoning if not handled correctly.

-

Injury to Workers: Excavation work involves heavy machinery and deep digging, which can lead to worker injuries if proper safety measures aren’t in place.

-

Environmental Hazards: Gas leaks can also lead to environmental damage, affecting soil and water quality.

Preventing Risks in Gas Excavation

To mitigate these risks, companies have adopted various safety practices:

-

Pre-Excavation Surveys: Comprehensive surveys to locate and assess gas lines are conducted before any excavation starts.

-

Use of Non-Invasive Techniques: In some cases, technologies like ground-penetrating radar (GPR) are used to detect underground utilities without disturbing the surface.

-

Continuous Monitoring: Gas concentrations are continuously monitored during excavation to ensure worker safety and to detect any potential leaks quickly.

-

Strict Safety Standards: Governments and agencies such as OSHA (Occupational Safety and Health Administration) provide strict guidelines to follow during gas excavation work, which contractors must adhere to.

The Future of Gas Excavation

With increasing urbanization, gas excavation is becoming more complex. New technologies, such as robotic excavators and drones, are being developed to improve the efficiency and safety of excavation work. Additionally, there is growing emphasis on replacing outdated gas lines with safer, more durable materials to minimize the need for future excavation.

👉 Explore the future of gas excavation technologies 👈

Conclusion

City gas excavation is a crucial process for ensuring the safe and efficient operation of gas networks in urban environments. Whether it’s for repairing old pipes, installing new ones, or performing routine maintenance, excavation work must be carried out with care, precision, and adherence to safety standards. The future of gas excavation looks promising, with technological advancements leading to even safer and more efficient methods. By understanding the process and its risks, we can appreciate the importance of this work in keeping our cities running smoothly.